___

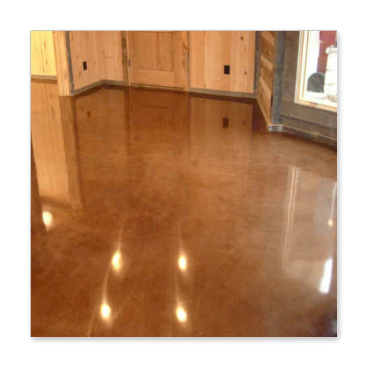

Polished Concrete Floors

Polished concrete floors are becoming the new favorite flooring alternatives, especially in high-profile retail and commercial settings to portray an ultramodern and minimalist design aesthetic.

Polished floor is concrete that has been ground with progressively finer grinding tools to a smooth, shiny, luxurious finish. Polishing makes use of the existing concrete, only removing the top layer (if any) at a fraction of the price of complete concrete overhaul.

Polished floors are durable, low-maintenance, and stain-resistant. A polished and sealed floor does not require regular waxing or buffing because the polishing process provides a permanent shine. Polished floors are aesthetically pleasing; can be designed and stained to include different colors and types of designs, including logotypes. Concrete can be polished to three different levels of sheen: matte, semi-glossy, and mirror-like glossy and all this, without breaking the bank.

The ‘industrial look’ is extremely popular in residential properties because it is easy to maintain and has a beautiful look with a glossy finish.

Polished concrete floors are used in:

- Retail stores

- Hotels and restaurants

- Office buildings

- Auto showrooms

- Residential properties

According to EPA (US Environmental Protection Agency) “concrete is a non-hazardous construction waste, that required to be disposed in a construction waste-specific landfill”, not in your plumbing system.

BENEFITS OF POLISHED CONCRETE

Polished concrete floors present significant advantages over other types of floor coverings, especially in terms of durability, cost, and aesthetics:

- Cost savings: Covering materials, such as carpet, tiles, or laminate are not necessary when the slab on grade is used as the finished floor surface.

- Easy to clean and low maintenance: Polished floors are easy to clean and to maintain, requiring only occasional mopping. They also eliminate the need for messy waxes or coatings as well as the associated work, time, and expense to apply them. Polished floors will not harbor dust, dirt, or allergens, and are water- and stain-resistant.

- Durability: Polished concrete is exceptionally durable and difficult to scratch or chip, which means it lasts long, long time. In contrast to ceramic tiles, Polished floors do not have to be replaced after a few years, because of low, broken, or dirty-looking grout.

- Available in wide variety of colors and designs

Can all concrete floors be polished?

Almost any structurally sound concrete floor, whether old or new, can be polished with proper preparation. However, floors that are wavy, spalled, need extensive patching, or are extremely porous may not be good candidates for polishing. Also, concretes that are been covered with glue for long time, may present discolorations (ghosting) that will be visible at the end of the polish process. Carpet tack repairs and patches would still show through after polishing.

If your concrete is less than perfect, the best option may be to apply a concrete overlay and polish it or apply an epoxy treatment.

A concrete specialist can determine if your concrete is polishable. Call us for a free inspection of your floor (703)880-8557

Wet or Dry Process?

There are two methods to polish concrete: wet process and dry process.

Wet process uses water to cool the machines. The grinding dust gets mixed with the water creating a semi-liquid mixture (slurry), which on some occasions and due to the pressure of the machine, splash all over the job site. To proper dispose the slurry, contractors need a filter to separate water from cement dust. If contractor does not have a filter, ask him how the concrete slurry will be disposed to make sure it is safe and in compliance with the environmental regulations. According to EPA (US Environmental Protection Agency) concrete is a non-hazardous construction waste, that required to be disposed in a construction waste-specific landfill, not in your plumbing system.

Dry process requires no water. Instead, contractors use machines equipped with dust-containment systems that eliminate virtually all the grinding dust. The dust is later carried away and properly disposed according to EPA and State regulations.

Heidelberg works exclusively with dry process.

Pictures of Polished Concrete Floors